-

Em obras provisórias é muito comum a utilização de sistemas rígidos compostos por vigas metálicas inclinadas em relação ao paramento, cujo objetivo é receber o tirante já na inclinação de projeto. Nesses casos, o reaproveitamento total ou parcial do sistema é oneroso e de difícil viabilização.

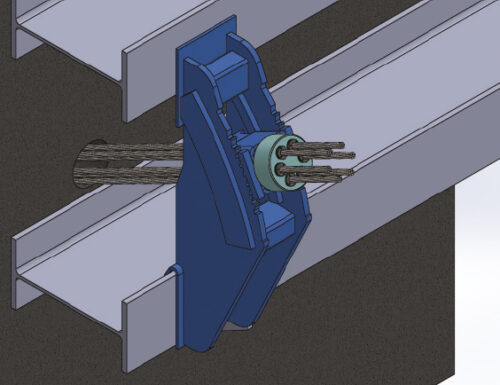

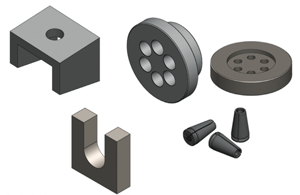

Diante desses problemas, a Incotep apresenta um sistema de ancoragem, composto por vigamentos metálicos e cabeça de ancoragem para os tirantes.

Para esse sistema demos o nome de Bracket.

Entre as principais características do Bracket, estão a redução considerável de tempo da necessidade de soldas e grampeamentos do sistema no paramento, já que os brackets são fixados à estrutura metálica apenas pela força normal aplicada pelo tirante e pelo atrito, o que permite o seu total reaproveitamento.

A função do Bracket é ajustar a cabeça de ancoragem ao grau do tirante, podendo variar de 15 à 37,5 graus. Este ajuste de ângulo é obtido através da parte móvel do Bracket que possui formato retangular, permitindo a passagem das cordoalhas e barras para montagem do conjunto. Ele pode ser utilizado para tirantes de barras ou tirantes de cordoalhas de 4,6 e 8 cordoalhas de ½” (carga de ensaio máxima 125 tf e carga de trabalho provisória de 83 tf).

-

The tubular Pipe Umbrella system is capable of increasing stability and safety in the work area, stabilizing not only the region of the cap, but also reflecting on the frontal stability, thereby mitigating the deformations in the rock mass induced by the excavation. It is an easy-to-implement system, which is one of the main advantages, due to the type and cost of the equipment used in the installation (Drilling Jumbo) and the low specialization of the workers, adapting perfectly to variations in geological conditions.

The tubular Pipe Umbrella system is capable of increasing stability and safety in the work area, stabilizing not only the region of the cap, but also reflecting on the frontal stability, thereby mitigating the deformations in the rock mass induced by the excavation. It is an easy-to-implement system, which is one of the main advantages, due to the type and cost of the equipment used in the installation (Drilling Jumbo) and the low specialization of the workers, adapting perfectly to variations in geological conditions. -

The Incotep Helical Pile is developed to meet the needs of projects, and can be produced according to the specific loads of each project. Designed with highly resistant materials against corrosion and easy to install, it represents an excellent solution for works where application deadlines are reduced.

The Incotep Helical Pile is developed to meet the needs of projects, and can be produced according to the specific loads of each project. Designed with highly resistant materials against corrosion and easy to install, it represents an excellent solution for works where application deadlines are reduced. -

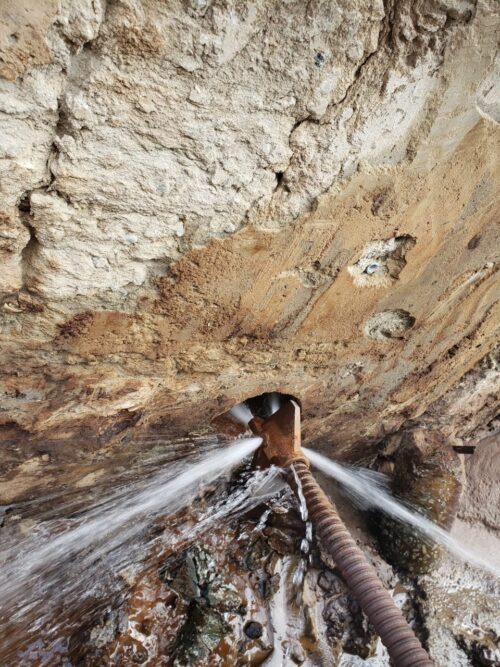

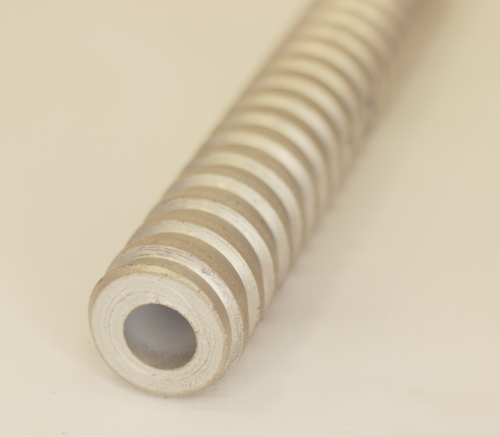

Produced from seamless tubes, they also undergo a cold rolling process to form the continuous thread with an exclusive profile. Incotep Hollow have as their main characteristic their high mechanical strength, which, combined with their hollow section, allows the rod to act simultaneously as a drilling and injection rod. For drilling, a special tricone drill is coupled, which will be incorporated into the rod, equipped with directional holes that inject the cement grout under pressure, allowing the formation of the anchoring bulb with a variable diameter between 200 and 300mm, depending on the rock mass profile where the tie will be anchored. The installation of the Hollow is also possible in mixed soil/rock or rock mass only, simply by attaching a drill bit with carbide buttons, also supplied by Incotep. In this way, at the end of the drilling process, the bolt will be automatically installed and injected, a methodology that gives the Hollow System a substantial gain in time in relation to the conventional anchoring process.

Produced from seamless tubes, they also undergo a cold rolling process to form the continuous thread with an exclusive profile. Incotep Hollow have as their main characteristic their high mechanical strength, which, combined with their hollow section, allows the rod to act simultaneously as a drilling and injection rod. For drilling, a special tricone drill is coupled, which will be incorporated into the rod, equipped with directional holes that inject the cement grout under pressure, allowing the formation of the anchoring bulb with a variable diameter between 200 and 300mm, depending on the rock mass profile where the tie will be anchored. The installation of the Hollow is also possible in mixed soil/rock or rock mass only, simply by attaching a drill bit with carbide buttons, also supplied by Incotep. In this way, at the end of the drilling process, the bolt will be automatically installed and injected, a methodology that gives the Hollow System a substantial gain in time in relation to the conventional anchoring process.

-

Prestressing Equipment Rental

Incotep, always thinking about engineering solutions, offers for rent hydraulic prestressing assemblies consisting of electric or manual pumps and hydraulic jack with their respective accessories. We supply cylinders with capacities between 15 and 300tf. The prestressing equipment complements the tie rod solution, as they allow the execution of tests and the incorporation of prestressing load provided for in NBR 5629-2018. Incotep also performs a Traceable Measurement of prestressing assemblies of up to 150 t, with the issuance of the respective certificate, guaranteeing quality and agility as the equipment is already calibrated for lease. Find out more details with our team.

-

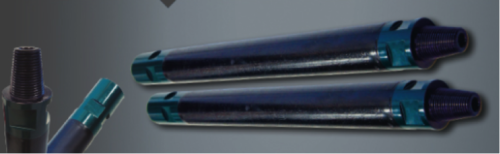

- Fabricadas com tubos sem costura de excelente qualidade e propriedades mecânicas especificadas pela norma API 5CT

- As ponteiras são confeccionadas em aço de alta resistência mecânica seguindo os perfis de roscas padronizados internacionalmente garantindo assim a montabilidade em qualquer equipamento. Estas ponteiras passam ainda por um posterior tratamento térmico o que aumenta a sua resistência ao desgaste e consequentemente sua vida útil

- Fazendo uso de uma das tecnologias mais avançadas e disponíveis atualmente, as INCO Hastes tem a junção das ponteiras roscadas feitas através do processo de solda por fricção (Friction Welding). As hastes produzidas seguindo este processo apresentam uma melhor performance em relação àquelas produzidas por outros métodos usualmente oferecidos no mercado

- Apresentam ainda um detalhe em ambas extremidades para a pega da chave o que facilita e agiliza a montagem e desmontagem em campo

- Ideal para máquinas Perfuratrizes de sistema rotativo de diversos diâmetros e para grandes profundidades.

-

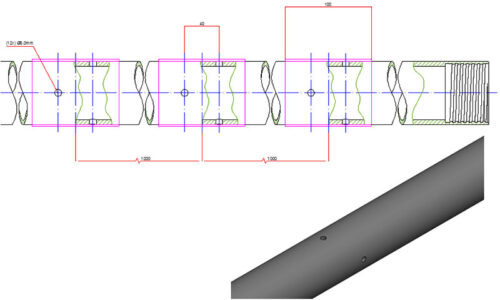

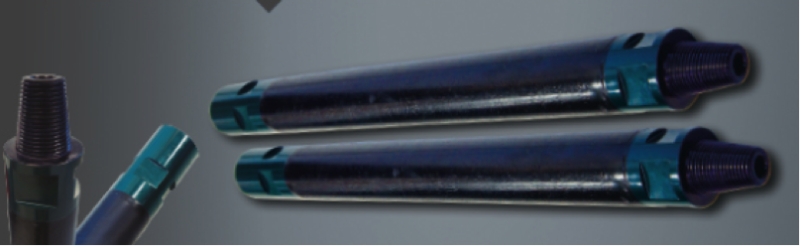

Casing Systems is the name of our self-drilling forepoling line. The system consists of an initial tube called Inco Rock Driling, which has a drill bit at one end, which is coupled to a central drill bit. The drill bit through the drill rods, give the system rotopercussive movement, promoting the drilling and advance drag of the forepoling tubes coupled in sequence. Our Casing Systems system is widely used in NATM tunnel works, in Manholes for lateral protection of walls during excavation (vertical forepoling) or even as injected micropiles to reinforce foundations.

Casing Systems is the name of our self-drilling forepoling line. The system consists of an initial tube called Inco Rock Driling, which has a drill bit at one end, which is coupled to a central drill bit. The drill bit through the drill rods, give the system rotopercussive movement, promoting the drilling and advance drag of the forepoling tubes coupled in sequence. Our Casing Systems system is widely used in NATM tunnel works, in Manholes for lateral protection of walls during excavation (vertical forepoling) or even as injected micropiles to reinforce foundations.