Mechanical properties

Check the mechanical properties of the standard ASTM A615:

| Mechanical properties | ASTM A615 Grade 100 |

|---|---|

| Fluency Limit, minimum (kgf/mm2) | 70,3 |

| Tensile Strength, minimum (kgf/mm2) | 80,5 |

| Stretching in 200mm, Mín. (%) | 7 |

Technical Characteristics

ASTM A 615 – GRADE 100

| Minimum Mechanical Properties [kgf/mm²] Grade 100 | Loads [tf] | |||||||||||||

| Limit Loads | Work according to standard ABNT NBR 5629:2018 | |||||||||||||

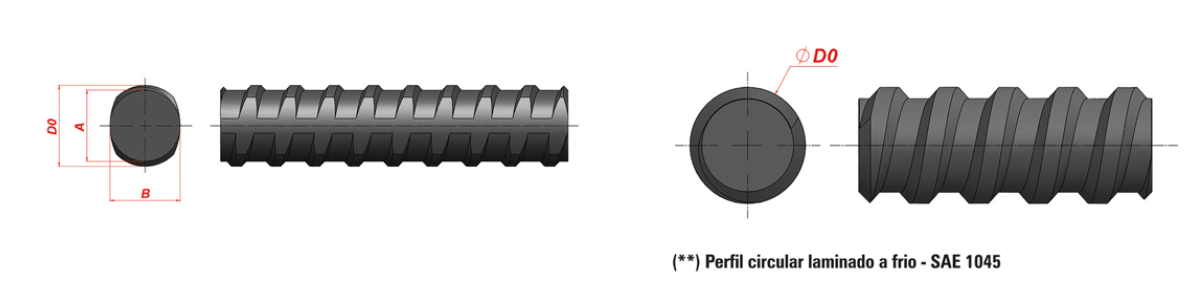

| Threadbolt Rods | Nominal Diameter [mm] | D0 – External Diameter [mm] | Core [mm] (*) | Area [mm²] | Linear Mass (*) [kg/m] | Flow Limit | Breakage Limit | Drain Load | Burst Load | Rehearsal | Permanent | Provisional | Load test | |

| Dimension A | Dimension B | |||||||||||||

| THB 16 (**) | 16 | 19,7 | Perfil Circular | 244,0 | 1,92 | 52,7 | 70,3 | 12,9 | 17,2 | 11,6 | 6,6 | 7,7 | 9,6 | |

| THB 19 | 19 | 20,9 | 17,7 | 17,9 | 276,0 | 2,13 | 70,3 | 80,5 | 19,4 | 22,2 | 17,5 | 10,0 | 11,6 | 14,6 |

| THB 22 | 22 | 24,0 | 21,8 | 21,0 | 390,0 | 3,06 | 70,3 | 80,5 | 27,4 | 31,4 | 24,7 | 14,1 | 16,5 | 20,6 |

| THB 25 | 25 | 26,8 | 24,0 | 23,5 | 475,0 | 3,73 | 70,3 | 80,5 | 33,4 | 38,2 | 30,1 | 17,2 | 20,0 | 25,0 |

| THB 32 | 32 | 37,1 | 32,2 | 31,8 | 804,0 | 6,87 | 70,3 | 80,5 | 56,5 | 64,7 | 50,9 | 29,1 | 33,9 | 42,4 |

| THB 36 | 36 | 38,0 | 34,8 | 31,6 | 998,0 | 7,85 | 70,3 | 80,5 | 70,2 | 80,3 | 63,1 | 36,1 | 42,1 | 52,6 |

(*) Linear mass is for reference only.

| Normal ABNT NBR 5629:2018 | |

|---|---|

| Maximum test load | = 0,90 x flow load |

| Permanent workload | = test load / 1,75 |

| Temporary workload | = test load / 1,50 |

| Load proof or short-term loads | = test load / 1,20 |

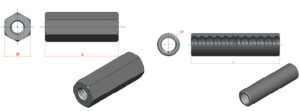

Splice Glove

| System | External Diameter D [mm] | L gauge [mm] |

|---|---|---|

| THB 16(*) | 34,92(*) | 100,0 |

| THB 19 | 38,1 | 110,0 |

| THB 22 | 38,1 | 115,0 |

| THB 25 | 48,3 | 145,0 |

| THB 32 | 60,3 | 175,0 |

| THB 36 | 60,3 | 210,0 |

(*) Hex Profile

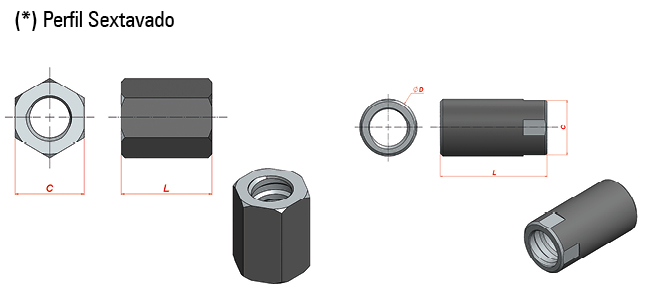

Anchor Nut

| System | External Diameter D [mm] | Length L [mm] | Key Dimension C [mm] |

|---|---|---|---|

| THB 16(*) | 34,92(*) | 40,0 | 34,9 |

| THB 19 | 38,1 | 55,0 | 36,0 |

| THB 22 | 38,1 | 60,0 | 36,0 |

| THB 25 | 48,3 | 60,0 | 46,0 |

| THB 32 | 60,3 | 90,0 | 56,0 |

| THB 36 | 60,3 | 110,0 | 70,0 |

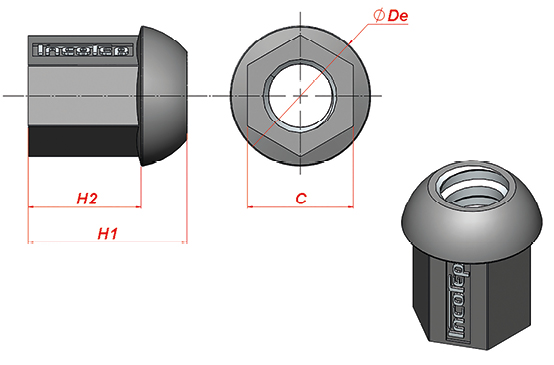

Concave Anchor Nut

| System | External Diameter [mm] | Height H1 [mm] | Height H2 [mm] | Key Dimension C [mm] | Mass [g] |

|---|---|---|---|---|---|

| THB 16 | 42,0 | 32,0 | 18,0 | 32 | 160 |

| THB 19 | 43,0 | 36,0 | 20,0 | 32 | 180 |

| THB 22 | 48,0 | 54,0 | 38,0 | 38 | 300 |

| THB 25 | 48,0 | 54,0 | 38,0 | 38 | 250 |

| THB 32 | 70,0 | 70,0 | 45,0 | 48 | 520 |

| THB 36 | 100,0 | 100,0 | 65,0 | 67 | 2200 |

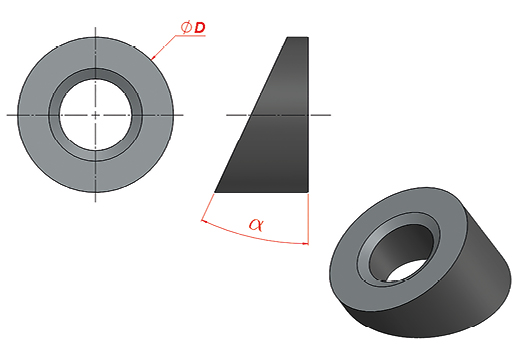

Degree Ring

| System | Diameter D [mm] | Angle a [Degree] |

|---|---|---|

| THB 16 | 48,3 | |

| THB 19 | 48,3 | 5°/ 10° / 15° |

| THB 22 | 48,3 | 20° / 25° / 30° |

| THB 25 | 63,5 | 35° / 40° / 45° |

| THB 32 | 63,5 | |

| THB 36 | 96,5 |

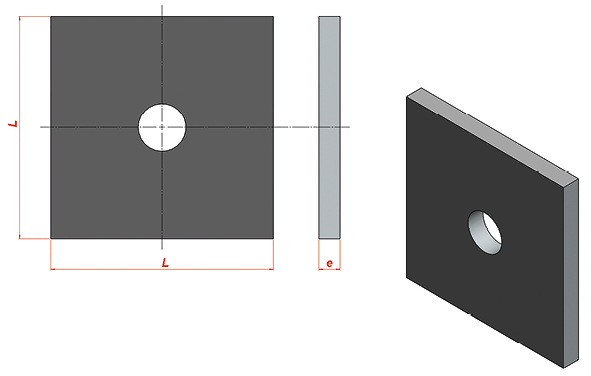

Anchoring Plate

| System | Dimensions L[mm] X L [mm] | Thickness and [mm] |

|---|---|---|

| THB 16 | 150 X 150 | 9,5 |

| THB 19 | 150 X 150 | 9,5 |

| THB 22 | 150 X 150 | 9,5 |

| THB 25 | 150 X 150 | 9,5 |

| THB 32 | 150 X 150 | 9,5 |

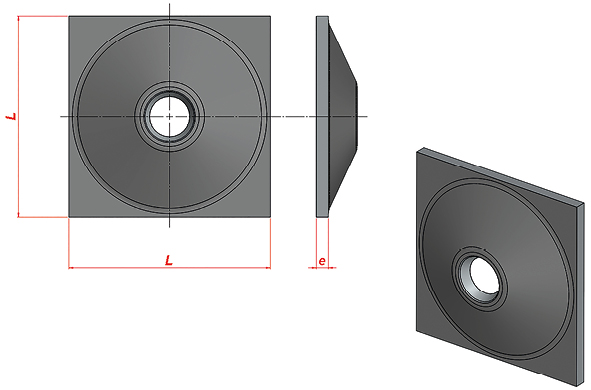

Concave Anchor Plate

| System | Dimensions L[mm] X L [mm] | Thickness and [mm] |

|---|---|---|

| THB 16 | 150 X 150 | 9,5 |

| THB 19 | 150 X 150 | 9,5 |

| THB 22 | 150 X 150 | 9,5 |

| THB 25 | 150 X 150 | 9,5 |

| THB 32 | 150 X 150 | 9,5 |