Wire Ropes

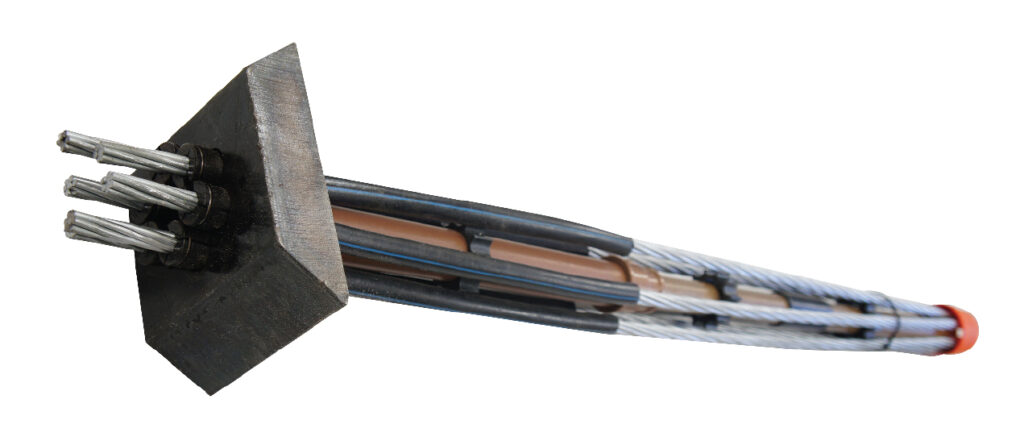

In this type of tie rod, the tensile-resistant element consists of 7-wire Wire Ropes, 6 of which are steel wires of the same nominal diameter, strung together through a helical twist, with a uniform pitch around a central wire. The supply of the Wire Ropes follows the classification of the ABNT NBR-7483 standard – Steel Wire Ropes for prestressed concrete, according to their tensile strength (kgf/mm²) and the type of behavior regarding relaxation, which may be RB or RN.

Description

Seven-thread wire ropes

The wire ropes have the following relaxation values after 1.000hs at 20ºC for an initial load of 80% rupture load: NR = 8,5% | LR = 3,0%. The average value of the modulus of elasticity is 202kN/mm².

Average coil dimensions

| Wire Ropes Types | Weight [kg] | Inner Diameter [cm] | Outer Diameter [cm] | Roll Width [cm] |

|---|---|---|---|---|

| 7 wires | 1500 – 3000 | 76 | 130 | 79 |

NOTES:

1. The outer diameter of the coil as well as its weight may vary depending on the length of Wire Ropes provided on the coil.

2. To avoid losses or reduce them, consult our team about lower weight reels.

Technical specifications of the most common prestressing Wire Ropes

| Product | Nominal Diameter [mm] | Approx. Area [mm²] | Minimum Area [mm²] | Approx. Mass [kg/1.000m] | Minimum Ultimate Load [kN] | Minimum Load at 1% deformation [kN] |

|---|---|---|---|---|---|---|

| Cord. CP 190 RB 12,70 | 12,7 | 101 | 99 | 0,792 | 187 | 169 |

| Cord. CP 190 RB 15,20 | 15,2 | 143 | 140 | 1,126 | 266 | 239 |

| Cord. CP 210 RB 12,70 | 12,7 | 101 | 99 | 0,792 | 203 | 183 |

| Cord. CP 210 RB 15,20 | 15,2 | 143 | 140 | 1,126 | 288 | 259 |

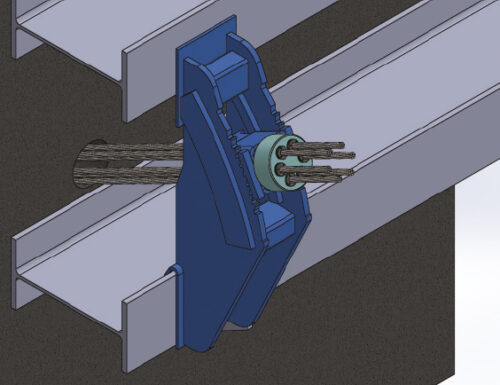

Devices for prestressing and mounting accessories

Incotep also supplies a wide range of accessories with the Wire Ropes.

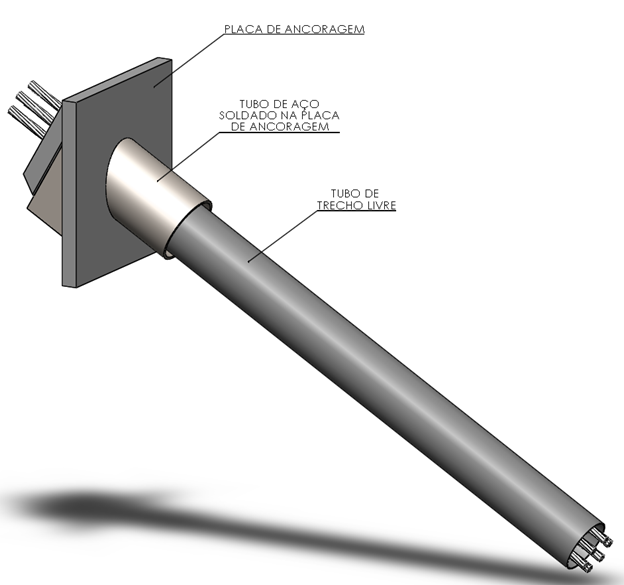

Wire Ropes tie rods need accessories such as spacers, rubber sleeves, ø16mm HDPE tubes (spaghetti), hoses for collective HDPE sheath and guide tips for their assembly.

For the application of prestressing to the tie rod, the components that integrate the anchoring head, Anchoring Plate with or without Grade Wedge, Anchoring Block and Wedges are required.

As this is an ANCHORING SYSTEM, it is important that the anchor block and the wedges are from the same supplier so that there are no incompatibilities in the application of loads. It should be noted that the reuse of wedges in prestressing is prohibited.

Anchoring Blocks

4 and 6 holes

| Model | Width A [mm] | Width B [mm] | Height C [mm] | Diameter D [mm] |

|---|---|---|---|---|

| 04 Holes | 155,0 | 115,0 | 44,45 | 63,0 |

| 06 Holes | 185,0 | 145,0 | 44,45 | 74,0 |

8 and 12 holes

| Model | Width A[mm] | Width B[mm] | Height C [mm] | Diameter D [mm] |

|---|---|---|---|---|

| 08 Holes | 137,0 | 137,0 | 63,5 | 101,0 |

| 12 Provisional Holes | 148,0 | 148,0 | 63,5 | 107,5 |

| 12 Permanent Holes | 177,0 | 177,0 | 63,5 | 121,0 |

Additional corrosion protections

The corrosion protection of the components that form the anchoring head of the tie rods is extremely important, since the vast majority of corrosion problems are concentrated in the free section, in particular close to the head or up to about three meters close to it. With this in mind and the concept of always offering complete and customized solutions to our customers, INCOTEP Sistemas de Ancoragem in addition to offering components (metallic sheaths, HDPE and LDPE pipes) and conventional treatments against corrosion (Epoxy painting, hot dip galvanizing) it also offers complements in order to guarantee that these protections.

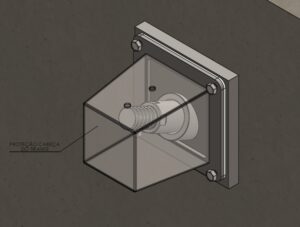

Metal shells (shape) and protective tubes

These are custom-made metallic forms, to be filled with mortar (when definitive) or grease (when it is necessary to perform checks on the tie rod over time), in order to protect the tie rod head components against corrosion. These forms are equipped with perforations where hoses for injection and breather (air outlet) are housed to complement the injection of the head.

Complementing the suggestion of the tie rod standard, for definitive tie rods, it is necessary to install a protective cover on the tie rod head, inserted 30 cm into the rock mass, to assist in the watertightness of the tie head.

See items C.3.2 and 8.2 of the standard ABNT NBR 5629-2018.

OPERATIONAL MANUAL FOR PRESTRESSING TIE RODS AT CONSTRUCTION SITES

OPERATIONAL MANUAL FOR PRESTRESSING TIE RODS AT CONSTRUCTION SITES

This manual was designed to guide the operator on the operational procedures to be followed in works for the application of our anchoring system. The execution of the tie rods, as well as the prestressing, must follow the design assumptions and mainly comply with the ABNT NBR 5629/2018 standard.

Guidance for Using the Block/Wedge Anchoring System

This manual was prepared to guide the customer on the procedures to be followed in works for the application of our anchoring system. The execution of the tie rods and prestressing must follow the design assumptions and mainly comply with the ABNT NBR 5629/2018 standard.