Self-drilling

Casing Systems is the name of our self-drilling forepoling line.

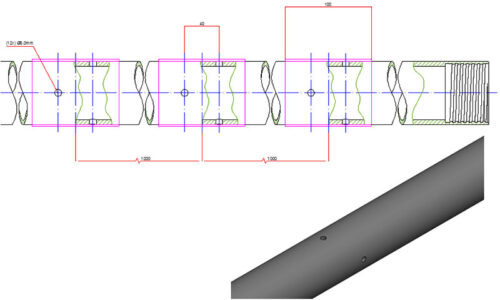

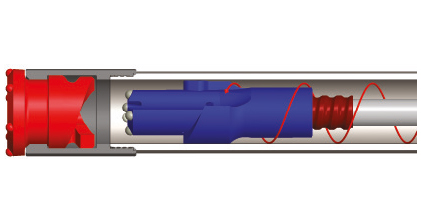

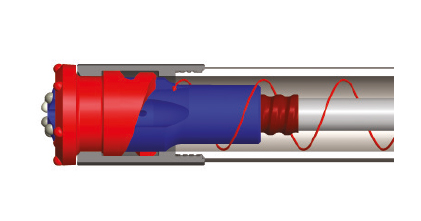

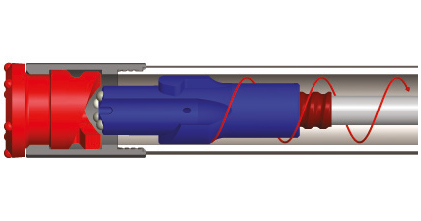

The system consists of an initial tube called Inco Rock Driling, which has a drill bit at one end, which is coupled to a central drill bit. The drill bit through the drill rods, give the system rotopercussive movement, promoting the drilling and advance drag of the forepoling tubes coupled in sequence.

Our Casing Systems system is widely used in NATM tunnel works, in Manholes for lateral protection of walls during excavation (vertical forepoling) or even as injected micropiles to reinforce foundations.

Description

Technical Chart

| Sistema Casing Systems | Yield Strength | Min. Yield [N/mm²] | Outer Diameter [mm] | Thickness [mm] | Linear Mass [Kg/m] | Standard Length [m] |

|---|---|---|---|---|---|---|

| INCO 73 | S355 A106 N80 St.34.2 |

355 240 562 205 |

73,0 | 6,40 | 10,51 | 3 |

| INCO 89 | 88,9 | 6,40 | 13,02 | 3 |

Main advantages

- Quality and uniformity in the drilling process;

- One-way locking system;

- Fast, safe and deviation-free drilling;

- Lower operational cost with higher productivity;

- Agility in execution;

- Specific models for each soil.

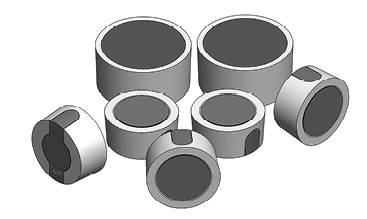

Acessories

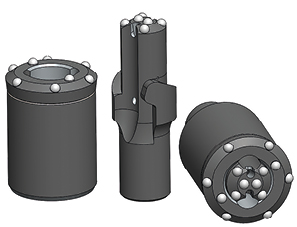

Inco Rock Drilling

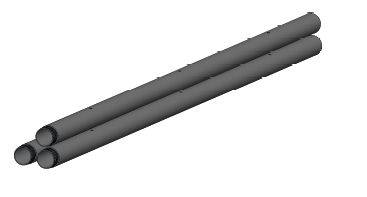

Inco Rock Casing

PVC Tube

02 a 20 bar Button Valve

Assembly Process – Self-drilling System

1° . Insert the pilot drill bit, attached through stems to the perforator machine, into the first coating tube which contains the drilling crown.

2° Turn the pilot drill bit counterclockwise so that it clamps in the drilling crown. At this moment, the Inco Rock Casing system is ready for the drilling.

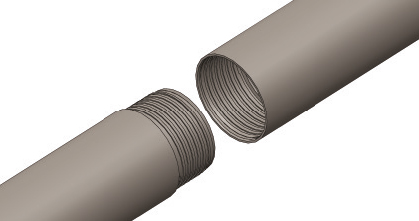

3° As drilling advances, join the coating tubes through male and female threaded connections until reaching the drilling length specified in project.

4° Upon finishing drilling, slightly turn it in the clamp opposite direction and remove the pilot drill bit.

5° Start a new drilling using a new coating tube with crown and the same pilot drill bit.